EPE Foam Factory Investment: Production Cost, Profit Analysis, and Efficiency Enhancement Guide

This document aims to provide investors planning to enter or currently operating EPE foam factories with a comprehensive, detailed, and actionable EPE foam cost-profit analysis report, while revealing core strategies for enhancing efficiency and reducing costs.

Part One: Key Considerations for Purchasing EPE Foam Production Lines (Essential Pre-Purchase Reading)

Before contacting any EPE foam machine supplier, clarify the following key points:

1. Define Your EPE Foam Market Positioning and Product Strategy

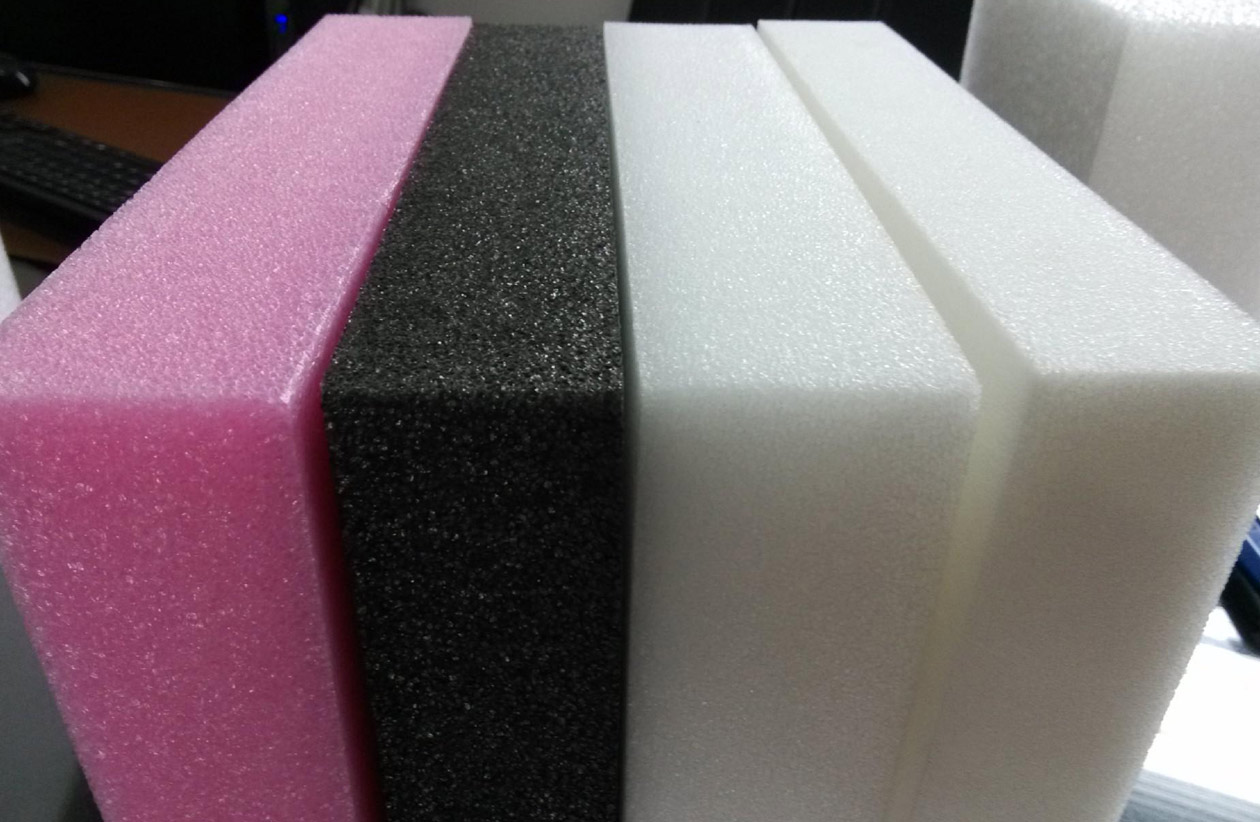

Product Type: What will be the primary production? Standard foam rolls/sheets? High-density EPE foam (45kg/m³ or higher)? Ultra-thin (below 1mm) or ultra-thick (above 20mm)? Do you require composite (laminated, foil-backed), flame-retardant, anti-static, or colored EPE foam? Requirements for core machinery vary significantly by product type.

Target Market: Are you supplying the local packaging market or producing export-grade premium products? This determines precision and stability requirements for equipment.

Production Capacity Planning: What is your projected daily/monthly output? This dictates the production line model and configuration.

Part Two: EPE Foam Machine Model Selection?

Many customers who are new to foam packaging industry are faced with the problem of how to choose a model when purchasing EPE machines. Many greenhands will choose the machine model according to their financial situation and sales volume. Actually this is not right.

EPE product is a kind of packaging material which is large is size but light in weight. This feature determines that its transport range is relatively limited. Therefore, when choosing an EPE foaming machine, it should be determined from the EPE needs of the surrounding target customers.

For example, the surrounding customers are furniture factories, door and window factories, ceramics, bathroom products and so on. Most of the EPE products used by this customer can be satisfied in the thickness range of 0.3-5mm. The door and window furniture factory will need U-shaped and other special-shaped materials. In this case, the 105/120 foaming machine can be selected, meanwhile, you can add the die head and auxiliary parts for making profiles Then it can meet the needs of surrounding customers.

If the surrounding customers are in packaging field—- electronic products packaging, wine packaging, gift box packaging, etc, this normally demands foam product thickness over 10mm. In this case, the customer needs a big machine -----180, 200, 220 or even 250. Big machine can make products which are thick with light density. Later when they make deep manufacturing the cost is lower and efficiency is high.

If customers wants to make thickness between 0.2-2mm, then it must be a small model of machine.

In general, big models of machines make products with thickness of more than 3mm, small models of machine makes products with thickness of 0.2-5mm. If you are not sure which model suits you, please contact us (Email:info@epesky.com) we can give you more detailed suggestions.

Part Three: All EPE Foam Equipment Prices (For Reference Only)

LongKou Runjie Machinery(LaiZhou Jinlida Machinery Co., Ltd) is oacted at Pinglidian industrial development zone belong to the coast of Laizhou Bay, the new 206 national highway, 169 kilometers. Where there with beauiful scenery and prosperity economic, thousands tonnage of Laizhou port run throughout the south and north, east and west, the traffic is convenient and unique geographical location. As the earliest company to make and innovate the plastic machinery In China is professional to make LPDE (high pressure low density polyethylene) foam board, sheet, pipe, rod, profile, net production line;EPE color-film coating machine; LDPE air bubble film machine; plastic net machinery, etc. We have lots of customers in the domestic provinces and cities. Market share has been accounted for 70%. We also export to Turkey, Romania, Mexico, India, Indonesia, Malaysia, Thailand, Vietnam, Russia, the United States, etc.

| Name | Product Description | EXW($) |

| EPE Foam sheet machine | EPE Foam sheet machine is mainly used to produce EPE foam sheet. Polyethylene foamed sheet/film, also named as epe foam, is a kind of new-type packing material with the features of dampproof, shockproofing, sound insulation, heat preservation and good plasticity. It is an ideal substitute of traditional packing materials. | 30,000.00~142,858.00 |

EPE Foam Tube/Rod/Profiles Extrusion Line | EPE Pipe/Bar/rod/profile machine can make EPE pipe, EPE net, EPE bar and other EPE profile. EPE foam pipe is used in the installation of air conditioner sheath, pipeline heat insulation, toy guardrail ,recreation places.EPE foam bar is widely used in the spring mattress, sofa terrier edge, seat cushion, sofa pillow and the shape, filling and decoration of high class clothes .EPE foam net is a kind of flexible packaging material ,widely used in glass products, precision instrument and fruit because of unique expandable mesh structure and good elasticity. | 24,285.00~42,858.00 |

| Fruit net machine | PE foaming net is a new type of flexible packaging material. Due to its unique expandable mesh structure and elastic foamed web, it is widely used in the packaging of glass products, precision instruments and various vegetables, fruits, flowers and other products. | 20,000.00~30,000.00 |

| EPE banana bag foam extruder | Banana bag tube-like EPE foam machine banana bag production line processing out of the products are mainly used for EPE banana pest control, anti-bird damage, and also can keep warm, is an important method of providing banana production and quality. | 42,570.00~58000.00 |

| PE Extrusion Laminating Machine | EPE Composite Coating Machine Applicable to laminating EPE foam sheet with PE film, OPP color film, Aluminum film, PVC, knitted cotton, LDPE or PP composite materials, aluminum foil, web paper, cloth and other substrates. It is suitable for the production of food packaging, medical packaging, baby crawling mats, moisture-proof mats, and greenhouses heat preservation quilt. The surface of the produced product is uniform, clear, strong concave and convex feeling, no bubble, high yield, and highly praised by customers at home and abroad. | 49,000.00~68,000.00 |

| EPE Foam Sheet Bonding Machine | EPE Foam Sheet Thickening Machine laminates thin EPE foam sheets into thick EPE foam sheet by method of gas flame or electric heating . With thickening machine, EPE foam sheets are thicker and stronger ,its use is more widely .We have two kinds of thickening machines: Gas flame thickening machine and Electric thickening machine . You can choose the most convenient method . | 7,000.00~10,000.00 |

| EPE Foam Sheet Cutting Machine | EPE Foam Sheet Cutting Machine is mainly used for automatic trimming and fixed length cutting of pearl wool sheet after compounding, and can cut pearl wool coil, sheet, EVA and so on. The machine adopts advanced microcomputer control, reliable performance, fast cutting speed, maximum cutting width of 2 meters, can meet various specifications, greatly improve production efficiency and reduce production costs. | 7,500.00~10,000.00 |

| Tube Rolling Machine | 1. The XPE/PEF/EPE sheet will be cut according to the required tube diameter 2.The cut XPE/PEF/EPE sheet will be coated with aluminum film or color film 3. And then bonded together through heat melting to form tubular packaging products. | 10,000.00~40,000.00 |

| EPE Foam Sheet Coating Machine | EPE Foam Sheet Coating Machine is the deep processing equipment of EPE foamed sheet/film products .It is used to laminate PE film, aluminum foil, plastic-coated paper , plastic –coated fabric etc. on the EPE foam sheet . It mainly includes six parts : laminating roller, rubber roller, temperature control system ,driving system, winding unit, and trimming unit .The machine adopts conduction oil as heat-transfer medium. | 8,000.00~10,000.00 |

| EPE Bag Making Machine | EPE Bag Making Machine is used to make bags with epe,bubble film and other materials. | 5,000.00~13,000.00 |

| 5-Layer EPE Foam Sheet Cutting Machine | Maximum slice width: 1350MM; . Maximum slice length:1500MM . Maximum slice speed:100 / MIN . Total power: 5KW . Dimensions: 3300X1750X2200MM (LхWхH) . The automatic lifting belt catch the material . Five-roll discharging rack | 2,000.00~7,000.00 |

| EPE Recyling Machine | 7,000.00~9,000.00 | |

| XPE Thickening And Laminating Machine | XPE laminating & bonding all-in-one machine is suitable for climbing mat embossing and thickening. It is used to produce climbing mats, yoga mats, picnic mats, and it can also make the most popular wall stickers at present. This machine is easy to operate, it makes clear embossing and it can save cost. | 12500.00 |

| 3d XPE Foam Wall Sticker Moulding Machine/XPE folding mat machine | 3D wall stickers are also called three-dimensional wall hangings and embossed wall stickers. They three-dimensional the walls people like, and at the same time strengthen the development and supporting of Wall stickers. The three-dimensional wall paste has certain hardness and flexibility, insulation, flame retardant, waterproof, anti-corrosion, non-deformation, anti-aging and other characteristics, and its service life is more than 20 years. | 58,000.00~80,000.00 |

| XPE Mat Broadside Cutting Machine for XPE Foam Wrestling Rollout Tatami Judo Mat | XPE Foam Wrestling Rollout Tatami Judo Mat Feature: · Easy to roll up and roll out, easy install the field · Light Weight, portable, durable · The mats are made from environmentally friendly cross-linked polyolefin foam, no odor and toxic (SGS report available). · High resilience and super soft touchness, excellent shock absorption · Anti-skidding surface,no static electricity · Print logo according to customer's requirements | 30,000.00~50,000.00 |

Part IV: EPE Foam Factory Operating Costs (Monthly Fixed Expenses)

These costs occur regardless of production activity:

Personnel wages: Approximately 8-12 employees, including general workers, machine operators, quality control, sales, and management. Total monthly payroll: ¥60,000 - ¥100,000 (based on China; adjust for other countries as applicable).

Facility Rent: 1,500㎡, monthly rent approx. ¥15,000–30,000.

Utilities: Electricity is the major expense (heating, traction, air compressors, etc.), averaging ¥30,000–60,000 monthly; water (cooling) is lower, approx. several thousand yuan.

Administrative Expenses: Office, logistics, travel, hospitality, etc., averaging ¥10,000–20,000 monthly.

Financial expenses: Loan interest, etc., subject to circumstances.

Taxes: Value-added tax, income tax, etc., tied to revenue.

Total monthly fixed operating costs: Approximately ¥150,000–250,000 ($21,000.00–28,500.00).

Part Five:How to calculate the production cost of EPE foam sheet?

1.The raw materials required for the production of EPE foam sheets is LDPE——-high-pressure low-density polyethylene resin (such as: TN26, 2426H, LD100AC, Russia 15803, Iran's TX00, 0190, etc. Generally speaking, as long as it is LDPE material and the melt index is 1.8 ~2.8, then it can be used), monoglycerides, talcum powder, butane gas.

2.Their current prices are:

LDPE low-density polyethylene resin (2102 TN26 produced by Qilu Petrochemical) $1377/ton

Monoglyceride (produced in Guangzhou) $1350/ton

Talcum powder (1250 mesh): $450/ton

Butane gas: $1180/ton

2. The amount of ingredients used for making EPE sheets:

LDPE pellets: 1000kg

Monoglycerides(GMS): 12 kg

Talc powder: 2.6 kg

Butane gas: 180 kg

3. Electricity consumption:

The actual consumption of electricity is about 4200 kwh in 24 hours, and the average output of EPE foam sheet is about 15 tons, so the power consumption per ton is about 280 kwh, The price of electricity is $0.1/kwh, and the electricity cost is: $0.1x280=$28.

4. Worker salary:

Every working day is divided into two shifts, with 5 people in each shift, and the daily salary per person is $30 (12 hours), and the daily EPE output is about 15 tons, so the salary for each ton of EPE is about $8.

5. Total cost of one ton of EPE foam sheet:

LDPE (low-density polyethylene) resin : $1377 * 1 ton =$1377

Monoglyceride(GMS): $1350 x0.012 tons = $16.2

Talc powder: $450x 0.0026 tons = $1.17

Butane gas: $1180 x 0.180 tons = $212.4

Electricity: $28

Worker's salary: $10

Total: $1644.77

Part Six: EPE Foam Factory Profit Analysis

I. EPE Foam Selling Price and Gross Margin

Market Price: Standard 20kg/m³ EPE foam rolls sell for approximately $2,100–2,500/ton. Customized and processed EPE foam products (e.g., laminated, custom-cut, colored, high-density) can command prices ranging from $2,300–3,500/ton or higher.

EPE Foam Gross Profit Calculation (using mid-range values):

Selling Price: $2,300/t

Cost: $1,645/t

Gross Profit = 2,300 - 1,645 = $655/t

Gross Profit Margin = 655 / 2300 ≈ 28%

II. EPE Foam Factory Break-Even Point and Net Profit

Monthly Break-Even Point:

Fixed Operating Costs ÷ Gross Profit per Ton = 25,000 / 655/t ≈ 38.1T

Interpretation: An EPE foam factory must produce and sell at least approximately 38.1 tons of EPE foam per month to cover all fixed and variable costs and reach break-even.

III. Monthly Net Profit Calculation for EPE Foam Factory:

Assuming monthly sales volume of 100 tons, generating revenue of $230,000.00.

Total Gross Profit: 100 tons × $655 = $65,500.00

Less Fixed Operating Costs: $28,600.00

Pre-tax net profit ≈ $36,900.00

Net profit margin ≈ 16%.

Conclusion: EPE foam production is an industry where “economies of scale” and “precise management” are highly evident. Higher output dilutes fixed costs to lower levels. Simultaneously, reducing variable costs—particularly polyethylene raw materials and energy consumption—through technology and management is key to boosting profitability.

Part Seven: How to Reduce Costs and Increase Profits in the Production of Pearl Cotton (Core Strategies)

I. Reducing Raw Material Costs (Highest Potential)

Process Parameter Optimization: Precisely control the barrel temperature of the pearl cotton foaming machine and the die head pressure to find the optimal foaming balance point. Minimize excess butane injection while ensuring the integrity of the cell structure.

Scientific Use of Recycled Materials:

Thoroughly clean and shred production scraps and defective products using a crusher. Blend these recycled materials with virgin resin at a ratio of 5%-50%. This approach not only directly reduces procurement of new polyethylene and related additives but also partially improves processing properties. Crucially, maintain a stable addition ratio and conduct rigorous product testing to ensure core customer product quality remains unaffected.

Centralized Procurement and Strategic Partnerships:

Establish long-term collaborations with 1-2 major petrochemical distributors or manufacturers to secure volume discounts. Closely monitor LDPE futures and spot market trends, increasing inventory appropriately during price lows.

II. Reducing Energy Costs

Equipment Selection and Maintenance:

Procure energy-efficient main units equipped with servo motors and high-efficiency heating coils.

Regularly clean cooling towers to maintain heat exchange efficiency; promptly service air compressors to minimize leaks.

Production Planning Optimization:

Prioritize continuous production runs to reduce energy waste from frequent startups and shutdowns (each startup involves preheating and process stabilization, resulting in high energy consumption and increased scrap).

Batch orders of identical specifications and colors to minimize mold changes and machine adjustments.

III. Enhancing Production Efficiency and Yield Rate

Minimizing Start-up Scrap and Process Losses:

Optimize start-up procedures to shorten the time from material feeding to stable production.

Enhance employee training to minimize defects caused by operational errors, such as material breaks or uneven thickness.

Optimize blade arrangement for slitting and cutting processes to improve material utilization.

Improve Overall Equipment Effectiveness (OEE):

Implement preventive maintenance to reduce unplanned downtime.

Employ technical solutions (e.g., automatic roll change and winding) to ensure consistent length per roll of pearl cotton, minimizing waste from subsequent laminating and thickening joints.

IV. Enhancing the Value-Added Potential of EPE Foam Products (Increasing Selling Prices)

Transitioning from an “EPE Foam Material Supplier” to an “EPE Foam Solutions Provider”:

Instead of merely selling EPE foam rolls, offer integrated solutions encompassing EPE foam design, cutting, lamination, and packaging. A custom-shaped EPE foam packaging component tailored to a client's product yields significantly higher profit margins than standard rolls of equivalent weight.

Developing High-Value-Added EPE Foam Products:

Prioritize promoting functional materials like anti-static EPE, flame-retardant EPE, and aluminum foil-laminated EPE, which feature higher technical barriers and profit margins.

Develop colored pearl cotton to meet brand clients' visual packaging demands.

Focus on Premium EPE Foam Clients:

Proactively target industry clients less price-sensitive but demanding in quality, delivery, and service—such as those in high-end electronics, medical devices, and cold chain logistics.

V. Strengthen EPE Foam Factory Management and Data Analysis

Establish a consumption assessment system:

Conduct precise statistics and assessments for each EPE foam production line and shift regarding “LDPE consumption per ton of product,” “butane consumption per ton of product,” and “electricity consumption per ton of product,” linking these metrics to performance evaluations.

Establish an EPE Foam Process Parameter Database:

Record complete parameters (raw material batch, temperature, pressure, speed, etc.) for every successful EPE foam production run. When reproducing similar products, quickly retrieve optimal parameters to minimize setup waste and stabilize quality.

Summary

Operating a successful EPE foam factory extends far beyond purchasing equipment, sourcing raw materials, manufacturing, and selling. It is a comprehensive competition encompassing “EPE foam technology and process,” “EPE foam cost control,” and “EPE foam market positioning.”

Key to Initial Success for EPE Foam Factories: Acquire stable, energy-efficient, and safe equipment, and hire an experienced, highly responsible machine operator.

Core to long-term profitability: Implement meticulous cost management at every production stage while continuously ascending the value chain toward solutions and premium products.