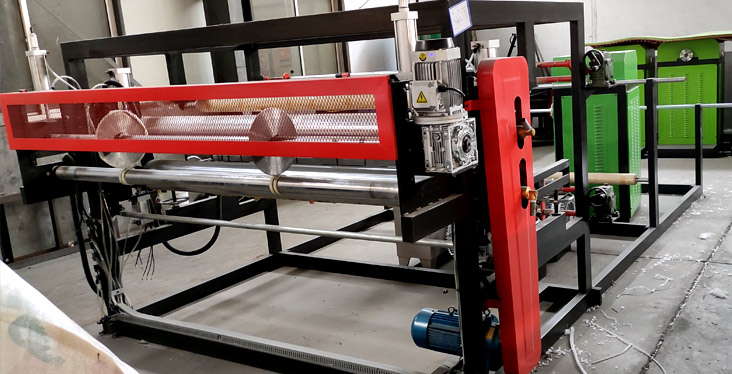

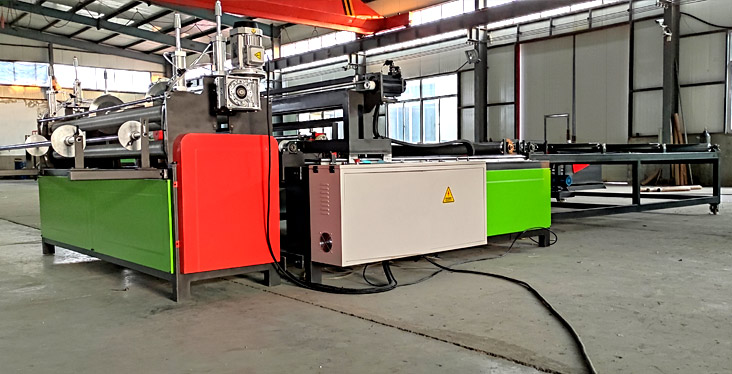

On-line cutting machine

The online cutting machine is composed of two parts: cutting part and conveying part. The length of the conveying part can be customized according to customers’ requirements. The online cutting machine is used to cooperate with the horizontal xpe/ixpe/epe foam sheet bonding machine to synchronously cut the bonded sheet, mostly used for thicker sheets.

The advantage to use this is that both bonding and cutting can be done at the same time which has a higher efficiency and save labor cost. The disadvantage of using it is that it has a tolerance of about 10mm, so it is only suitable for rough cutting, if you have a higher requirement of the cutting length, it is not suitable.

The online cutting needs to be made during the moving of the sheets—-EPE, XPE, IXPE or EVA, etc. Because of the distance of the slide-way, the current shortest cutting length is 1.5m.

The online cutting machine is suitable for customers who specialize in customizing thick foam planks. During the process of bonding, if the thickness of foam planks is more than 30-50mm, it is difficult to roll it. As a result, many manufacturers don’t roll the planks after they reach a thickness of 30mm.

Instead, they pile them up and when they bond the planks again, they bond it directly. In this case, the labors work harder. If you use online cutting machine, then it can cut the bonded foam planks to a suitable length, and next time when you bond it again, it is much easier.