What machines are needed for making play mats?

There are two kinds of play mats in the market now: One is EPE mat, the other is XPE mat. If you want to make foldable mats, you had better use XPE as material. For EPE mats, they are normally rolled. If you do want to make EPE foldable mats, it is okay, but the quality is not as good as XPE mats——the embossing on the mat surface is not so good and the folded part is not so good as XPE mat, either.

For making foldable XPE mats, if you buy XPE sheet, then the machines you need are: lamination machine (either thermal lamination machine or extrusion lamination machine is ok), thermoforming machine. But if you want to make rolled EPE mats, if you buy EPE sheets, the machines you need are: extrusion lamination machine and cutting machine. You can make EPE sheets by yourself because EPE sheet extruder is much cheaper than machines that makes XPE sheet.

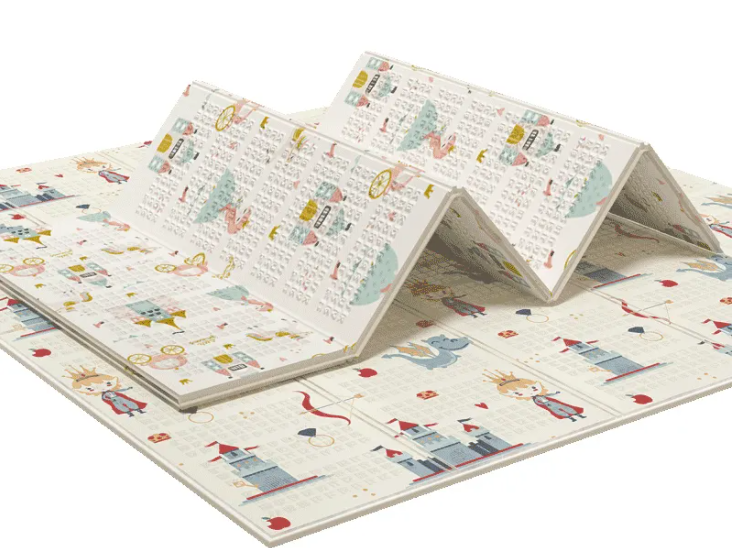

Advantage of XPE mats is that it is foldable so it is easier to carry, but its disadvantage is that it is more expensive. EPE mats are much cheaper, but its disadvantage is that it is not so easy to carry.

If you want to make both types of mats, then you can buy the following machines: extrusion lamination machine, thermoforming machine, cutting machine. In this way, you can make not only foldable XPE mat but also rolled EPE mats.