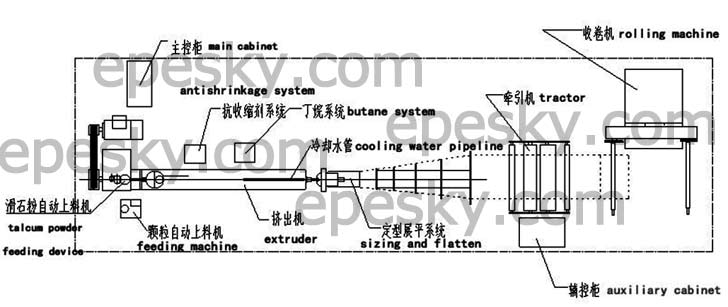

The structure of the epe foam production line(pe foam sheet extrusion line)

epe foam production line(pe foam sheet extrusion line) The drive system

The drive system is the power source of the extrusion. It is made up of motor, plastic machine dedicated reducer, belt pulley and the triangular belt.

Power is transmitted to gear box through belt pulley、triangular belt by motor, and transmitted to screw through gear reduction by gear box. The motor is three-phase asynchronous motor, rated voltage is 380V, 50HZ, frequency control of motor speed, speed controlling stable, reliable, energy efficiency more higher than electromagnetic speed controlling. The reduction gear is the dedicated reducer for plastic machine, which is with great bearing capacity, durable in use, not easy to damage.

The extrusion system of the epe foam production line(pe foam sheet extrusion line)

The screw and barrel is the core part of the extrusion system, which is bearing the task of material transporting, plasticizing, homogenizing, mixing and foaming. The material of screw barrel is: 38CrMnAlA,through hardening and tempering, nitrogen treatment, has the feature of wear-resisting, corrosion resistance, long service life.

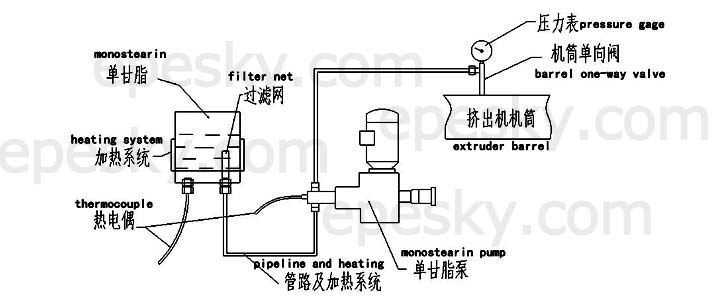

Monostearin input system of the epe production line,pe foam sheet extrusion line

Monostearin is the anti shrinking agent, and has the lubricating property at the same time. Which is the solid under the normal temperature, with granular surface, or powdery.This production line heats the monostearin, melt it into the liquid, then injecting it into the barrel through the pressure meter pump. The monostearin input system is made up with heating tank, heating metering pump, one-way value, pressure gage, heating pipe.

The monostearin input system flow chart:

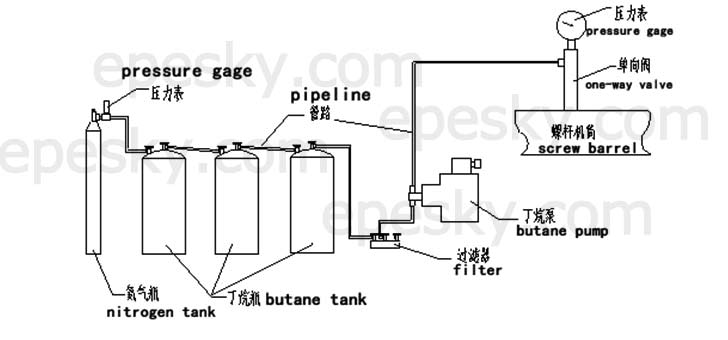

Butane input system of the epe foam production line

Butane is the foaming agent, which is inputting into the barrel by the metering pump. Butane system is made up of nitrogen cylinder for pressuring、butane tank、filtering tank、metering pump、one-way value、pressure gage and pipe , due to the butane is flammable, so the metering pump motor adopts the explosion- proof motor.

Butane system flow chart:

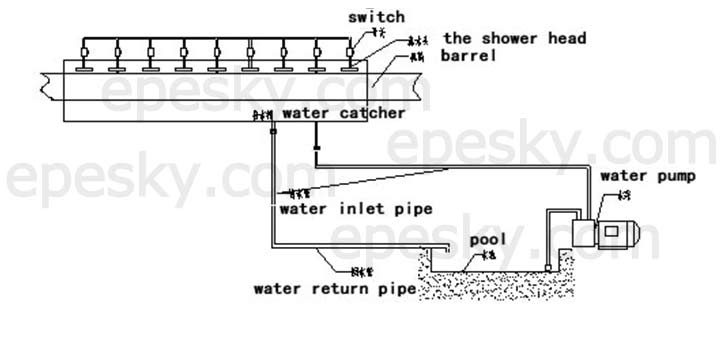

Cooling system of the pe foam sheet extrusion line

Cooling system is the water cooling style, which is controlled by the temperature controller, is made up of the water tank, water pump,water value,magnetic value, pressure gage, and pipe. The flow chart is as following:

Heating system of the pe foam sheet extrusion line

The heating system mainly includes barrel heating part, machine head heating part, and the monostearin charging basket, pipe, pump head heating part, which is made up of the thermocouple, temperature controller, heating ring, or heating belt.

Screen net changer of the pe foam sheet extrusion line

During the production line running, it’s hard to avoid the impurities in the materials, this impurities will has a strong impact on the products quality , so we have to add the screen exchanger. The screen exchanger has hand-operated and automatic, user can note it on contract based on yourself requirement。Hydraulic automatic screen exchanger can handle the net changing work within a few seconds under the condition of non-stopping working. But the hand-operated need to stop the machine.The filter net in the screen exchanger is easy to be blocked by the impurities ,so we need to change the filter net for often based on the actual condition.

Foaming head of the pe foam sheet line

The machine head is the part for foaming and shaped of product, the ready product thickness is mainly depend on the gap size of die and the hauling speed of traction machine, the width or ready product is mainly depend on the die diameter and the diameter of sizing drum.

Sizing device of the pe foam sheet line

The sizing drum of sizing device is very important for foam sheet width and smooth of surface, so we should choose the suitable sizing drum based on the requirement in sheet width. In order to reduce the friction between foam sheet and sizing drum, generally to wrapping a cotton cloth on the surface of sizing drum. There is 4 air intake of air ring in sizing device, the air transporting from fan through the distributor and wind duct enter into the vane through such air intake, then blow-out through the vane air outlet, to cooling the foam sheet, and sizing.Subdivision part is to axial slit the cylindric foam sheet, making preparation for the flatten. This part uses one electric motor to drive one circular blade to cut the foam sheet through turning, the direction of the blade rotation is in the opposite of the sheet traction.

Flatten frame of the pe foam sheet extrusion line

The flatten frame flattening the cutting foam sheet from cylindric shaped.

Tractor of the pe foam sheet extrusion line

This device has the function of traction, metering, and flatten for foam sheet, the traction speed is controlled by the frequency control motor, to realize the infinite speed. The length gage is controlled by meter counter, the length can be free to set, it will automatic alarm when reaching the set length.

Rolling machine of the pe foam extrusion line

This device is double-station rolling, the exchanging of station is controlled by meter counter,roll-over the motor to drag the roll-over device to realize the exchanging. Rewinding shaft has A and B part, they are controlled by one set torque motor separately. The rolling alternation process is: when A roller is reached the set meter, the alarm system will bell under the controlled of meter counter, roll-over system starts to work, the double shaft turns, the A roller continuously turns to rolling, the double shaft will stops when it is 180 degree, the roller B will starts to work before the double shaft stopping. At this time, the right hand rip the foam sheet near B roller by the blade, the left hand pull the foam sheet on the B roller, the B roller starts to work, then worker put down the foam sheet from A roller, install the new paper tube, to finish the changing work, when the B roller is reached the setting data, to repetition the above action.

Electric control of the pe foam extrusion line

The electric system includes the control cabinet and the auxiliary control cabinet. The control cabinet controls the main motor、heating system、 barrel cooling system、sizing blower、the wind ring fan、butane inputting and monostearin inputting system. The auxiliary control cabinet controls the traction machine and rolling machine. Details please see the 11 unit electric system.