What is the principle of EPE foaming machine

In the production process of EPE packaging materials, physical foaming is used instead of chemical foaming. At present, the most common way of foaming is to use butane gas as foaming agent. If there is no butane gas, LPG, methane or propane can also be used as substitutes for butane . At the same time, many EPE product manufacturers in China are trying to replace butane gas with carbon dioxide as foaming agent.

How to calculate the production cost of EPE sheet?

1.The raw materials required for the production of EPE foam sheets is LDPE——-high-pressure low-density polyethylene resin (such as: TN26, 2426H, LD100AC, Russia 15803, Iran's TX00, 0190, etc. Generally speaking, as long as it is LDPE material and the melt index is 1.8 ~2.8, then it can be used), monoglycerides, talcum powder, butane gas.

How is the moisture-proof & thermal-insulation camping pad made?

Xpe foam baby mat is environmentally friendly, non-toxic, and has no peculiar smell. It is an environmentally friendly material recognized by the world; it will not cause any side effects on the baby's tender skin. Compared with epe baby mat, it is not easy to deform and restore It is more durable and more comfortable. The only disadvantage is that the price is high.

What is the complete set of machines to make XPE foam baby mats?

Xpe foam baby mat is environmentally friendly, non-toxic, and has no peculiar smell. It is an environmentally friendly material recognized by the world; it will not cause any side effects on the baby's tender skin. Compared with epe baby mat, it is not easy to deform and restore It is more durable and more comfortable. The only disadvantage is that the price is high.

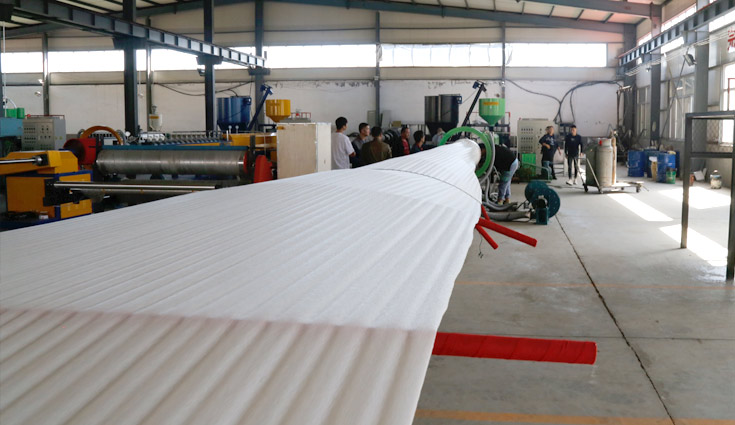

Detailed application of different types of pe foam machine(pe foam sheet extrusion line)

Model 55 pe foam machine (pe foam sheet extrusion line)

Model 75 EPE extruder (pe foam sheet extrusion line)

Due to the low output of Model 75 EPE extruder, it is almost not used in China for using it to make EPE sheet.

What’s the difference between EPE baby mat and XPE baby mat?

1. Environmental friendly

In terms of environmental protection, both epe baby mat and XPE baby mat are environmentally friendly and odorless, and you can use them without worries.

2. Service life

What is the complete set of machines to make XPE foam baby mats?

Xpe foam baby mat is environmentally friendly, non-toxic, and has no peculiar smell. It is an environmentally friendly material recognized by the world; it will not cause any side effects on the baby's tender skin. Compared with epe baby mat, it is not easy to deform and restore It is more durable and more comfortable. The only disadvantage is that the price is high.

The most complete knowledge so far about baby crawling mat purchasing

1. Fiber (cloth) crawling mat

Most fiber crawling mats sold online are under the name of "cotton crawling mats". In fact, they are not really pure cotton. It has a sandwich structure: the fabric is usually pure cotton, the base material is polyester fiber (with non-slip particles), and the main material in the middle is polyester fiber (PET synthetic fiber) or absorbent cotton (natural fiber).

What is the complete set of machines to make XPE foam baby mats?

Xpe foam baby mat is environmentally friendly, non-toxic, and has no peculiar smell. It is an environmentally friendly material recognized by the world; it will not cause any side effects on the baby's tender skin. Compared with epe baby mat, it is not easy to deform and restore It is more durable and more comfortable. The only disadvantage is that the price is high.

How to choose a suitable EPE extruder model for making EPE climbing mat?

Epe foamed sheet is an environmentally friendly packaging material. It can be naturally degraded and decomposed after being irradiated by ultraviolet rays. The production process is environmentally friendly, too. Because of the good protection effect, and because it is a relatively cheap and affordable floor mat product in the market. It is popular with many people in the world.

«2345678910111213141516»