Model 120 EPE foam sheet making machine

The sheet thickness range made by Model 120 EPE foam sheet making machine is 0.5-7mm. (for width 900-4000mm). As the machine output is fixed, (for model 105, it is about 180kg/h), the wider the sheet is, the thinner the thickness is.

Under what circumstances can recycled EPE materials be used

Model 135 EPE sheet extruding line

Model 135 is medium-size EPE sheet extruding line. It can make EPE sheet with thickness 1-9mm (corresponding to width 1m-4m, the wider, the thinner).

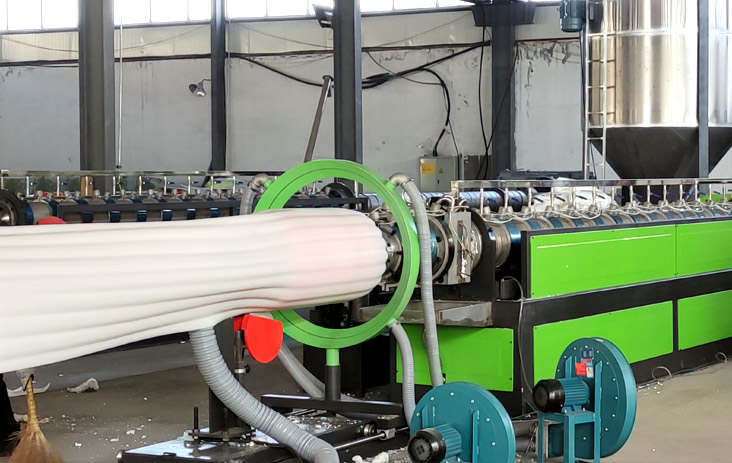

150mm EPE foam sheet extrusion line

Model 150 means the screw diameter is 150mm. As the L/D ratio is 55:1, the screw length is 150x55=8250mm. Adding the die head, motor, gearbox, the main extruder length is about 10m. With its auxiliary parts, it needs a workshop of 32m long. Its output is about 300kg/h, and it can make EPE sheet with thickness of 2mm-12mm. (corresponding to the width 1m-4m). Its total installed power is 220kW and real electricity consumption is 120kWh.

75mm EPE Foam Extruder

Due to the low output of Model 75 EPE extruder, it is almost not used in China for using it to make EPE sheet.

The key steps of making degreasing EPE sheet

Degreasing EPE sheet is also called wax-free EPE sheet or oil-free EPE sheet. The way of making such sheet is different from that of making normal EPE sheet. During the process of making degreasing EPE sheet, no GMS (monoglyceride) is added.

Is the EPE production line dangerous?

Vertical epe foam bonding machine and horizontal epe foam sheet bonding machine

There are two types of epe foam bonding machine in terms of thickness and ways of operation:

Vertical epe foam bonding machine and horizontal epe foam bonding machine.

PE foam extruder machine

With our PE foam extruder machine , engineers with good technology can easily make epe foam products with density of 16kg/m3. Some of our customers can even make products with density of 14.5kg/m3. Let's compare the profit: if you make density 18kg/m3 products, you can get only 55m3 of products, however, if you can make density 16kg/m3, then you can get 62.5m3 of products. There is a big difference of your profit.

Solutions to the cracks of EPE sheet

EPE Foam Sheet Making Machine Complete Start-up Process / China Manufacturer [2020]

«456789101112131415161718»